- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

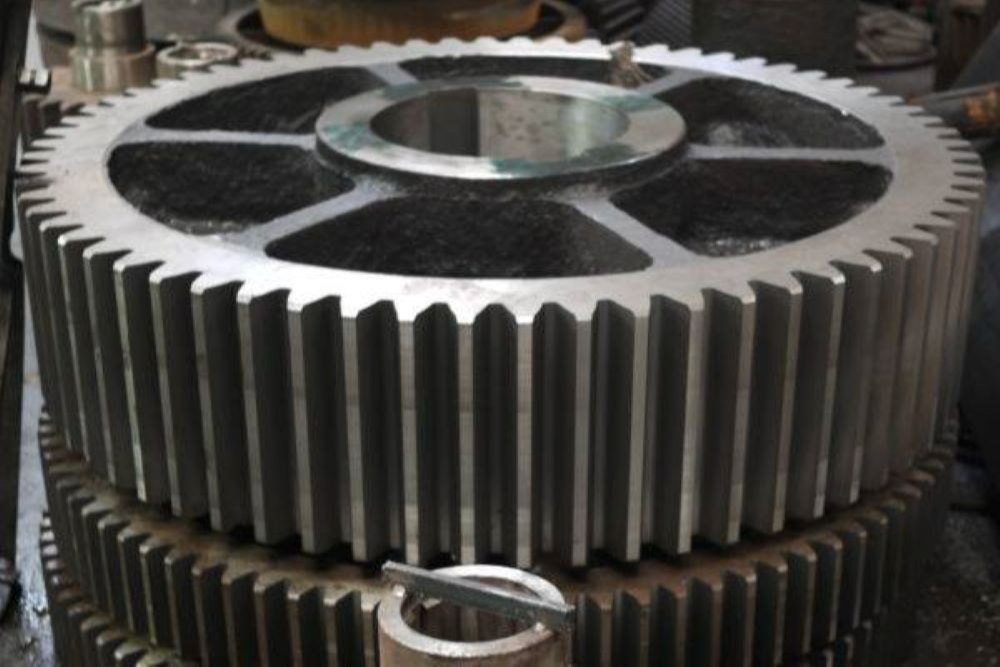

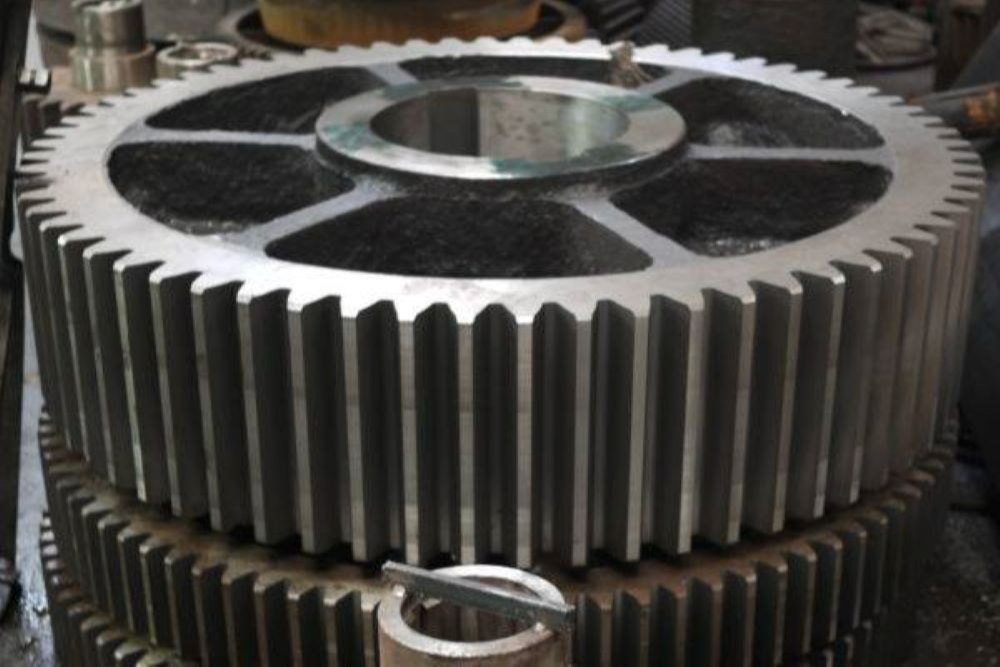

3600 Dia. Girth Gear

In the world of industrial machines, accuracy and durability are important. Cherry Belt Company is a well-known name in the manufacturing sector and a leader in providing high-quality mechanical components that meet the needs of modern industry.

What is a 3600-Diameter Girth Gear?

3600 Dia. Girth Gear is a large 3600mm diameter gear designed for rotary motion in large machinery and equipment. It is an important component in many industrial systems, providing torque and synchronization for smooth operation. Built with advanced technology and materials, our all-around equipment is designed to meet the highest standards of performance and durability.

Applications for the 3600 Dia. Girth Gear

The 3600 Dia. Girth Gear is designed for use in a wide range of industrial applications where strong and reliable rotary motion is required. Some of the main applications are:

Cement factories: In cement production, remote drives are an important part of rotary kilns and mills. The 3600-girth gear plays an important role in the smooth rotation of these large machines and ensures the smooth processing of raw materials and the production of high-quality cement.

Mining: Tools are used in a variety of mining equipment, including machines and mills. Ideal for handling heavy loads and critical conditions associated with mining, 3600 Dia. Girth Gear helps improve operational efficiency and reduce downtime.

Power plants: In power plants, high-speed equipment is necessary for the operation of large turbines and engines. The precision and durability of the 3600 Dia.girth gear ensure reliable performance in the demanding environment of power plants.

Steel industry: The steel industry relies on spur gears to operate large rolling mills and furnaces. The 3600 girth gear provides the torque and stability to handle the high forces involved in steel fabrication.

Construction equipment: Many large construction machines, such as cranes and excavators, often use remote controls for precise control and movement. The 3600 Dia. Girth Gear provides strength and reliability for the tough jobs performed by construction equipment.

Why choose a Cherry Belt company?

The Cherry Belt Company is known for its excellence in manufacturing high-quality mechanical components. Our commitment to quality, innovation, and customer satisfaction sets us apart from our competition. Why you should choose our 3600-girth gear:

User guide

Our team of experienced engineers and technicians brings years of expertise to design and manufacture our gear girth. We use the latest technology and best practices in the industry to deliver results that exceed expectations.

Customer-Focused Approach

We understand that every request is unique. Our customer support team works closely with customers to understand their specific needs and provide solutions that are appropriate, efficient, and effective.

Reliability and performance

With a focus on durability and precision, our rotary tools are designed to perform well under the most demanding conditions.

This commitment to quality results in lower maintenance costs and better management for our customers.

Comprehensive support

From initial communication to after-sales support, Cherry Belt offers comprehensive services to ensure a pleasant experience. Our technical support team is available to assist with installation, maintenance, and troubleshooting.

Features of 3600-Dia. Girth Gear

Durability and Strength

Our belt gears are designed to withstand the harshest operating conditions. Made from high-quality alloy steel and subjected to heat treatment methods, it is very strong and durable. This durability ensures that the device withstands heavy loads and prevents deformation over a long period of use.

Made right

At Cherry Belt, we take every aspect of our manufacturing process seriously. The 3600 Dia. Girth Gear is manufactured using advanced CNC machining techniques, ensuring that each gear is made to exact specifications. This precision ensures smooth operation, low noise, and low vibration in the operating machinery.

Properties

The gear teeth are specially designed and formed to fit the pinion wheel. This increases the ability to transmit torque and reduces the risk of gear slipping or failure. Gear teeth are subject to precise grinding for better performance and durability.

Customization Options

We understand that different applications are different, and we offer customization options for our tools. This includes changes in tooth grades, material grades, and tool configurations to meet specific operational needs.