- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

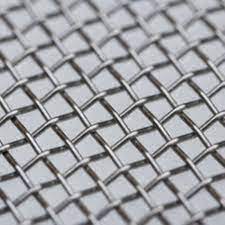

Mining Wire Mesh

Mining wire mesh is a necessary commodity in mining and drilling industries to reinforce rocks, enhance safety measures, and as meshes for screening among others. CHERRY manufacturing focuses on high-end mining wire mesh suitable for the abrasive atmosphere and strain of mines. From stainless steel and galvanized wire, these meshes are known for their strength, and resistance to corrosion and flexibility. When deployed in the low visibility subterranean mining environment or the more exposed opencast mining environments, CHERRY’s mining wire mesh delivers enhanced performance in productivity and safety. CHERRY upholds its name in offering quality wire mesh by installing innovative and reliable concepts to supply products that fit the industry required standards making it a preferred supplier of wire mesh products to the mines all over the globe.

Mining Wire Mesh Manufacturer

CHERRY is a well-known manufacturer of mining wire mesh since the company focuses on manufacturing and supplying excellent products that can effectively suit the mining industry’s requirements. CHERRY assures its customers of high-quality wires and wire mesh sizes, ranging from fine to coarse to suit various purposes. Every one of them is made with sturdy material that offers the best for any kind of physical deterioration in demanding situations. On production techniques, the company’s advanced techniques ensure that the wire mesh has high tensile strength thus suitable for reinforcement of rock, screening, and filtering. It emerged that CHERRY recognized the importance of quality and customers hence becoming a partner of choice for mining companies that require high quality and long lasting wire mesh.

Mining Wire Mesh Supplier

CHERRY specializes in the supplying of mining wire mesh and has available a broad spectrum of product options about the type of wire mesh to meet the mining requirements. The available options include various mesh sizes and kinds of square mesh, rectangle mesh, and welded wire mesh to meet the customers’ demand for various applications. CHERRY’s mining wire mesh contains flexibility and strength for use in both underground and surface mining. The company values its products by using first-grade materials that are highly resistant to corrosion and wear hence durable. Therefore, this study aims to ensure customer satisfaction by providing high-quality and efficient wire mesh products that are underneath the concept of safety in the mining industry.

Mining Wire Mesh Price in India

The price of mine wire mesh in India is again influenced by the type of wire that is used in the manufacturing process, size of wire mesh and the technique applied in it. In fact at CHERRY, we endeavor to ensure that we meet the customers expectations of getting the necessary value for the amount of money that they spend by standardizing the prices to reflect the value. Our mining wire mesh is mostly produced using stainless steel or galvanized wire which is costly but provides you with the best value for your money. Another advantage of this model is that there are no extra or hidden charges for the customer to pay before making a decision. Further, we offer customized services based on the needs of a particular project hence making our product operational in numerous markets though at different price ranges without compromising the quality of the service to be offered.

Why CHERRY Is the Best Brand For Your Mining Wire Mesh?

High Durability

CHERRY’s wire mesh is created to endure the extremities of the mining activity to provide long-lasting and dependable services.

Versatile Applications

The use of metals can be for screening, separation, and reinforcement and their products target various aspects of mining industries.

Cost-Effectiveness

A wire mesh is not easily damaged thus lowering the frequency at which it needs replacement and increasing the efficiency of CHERRY’s operations.

Safety Features

Many options are more safety-oriented, and CHERRY focuses on mesh options that enable the structure to be as sound and safe as possible while dealing with mining dangers.

Mining Wire Mesh Features

High Tensile Strength

Welded wire mesh has tensile capabilities of up to 550 Mpa to provide support in high rock stress conditions.

Corrosion Resistance

STS offers wire mesh products Suitable for extreme mining environment; Through rust and corrosion resistance.Collections: Galvanized or stainless steel wire mesh.

Customizable Sizes

The product is produced in a range of length ( options from 1500mm to 6000mm.. ), width (from 1200mm to 2400 mm), wire diameter (from 3.15mm to 5.6mm), and aperture sizes (100x100mm) depending on the strata control needs from the client.

Woven or Welded

Woven wire mesh has flexibility and welded has higher tensile strength for those regions having seismic risk.