- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

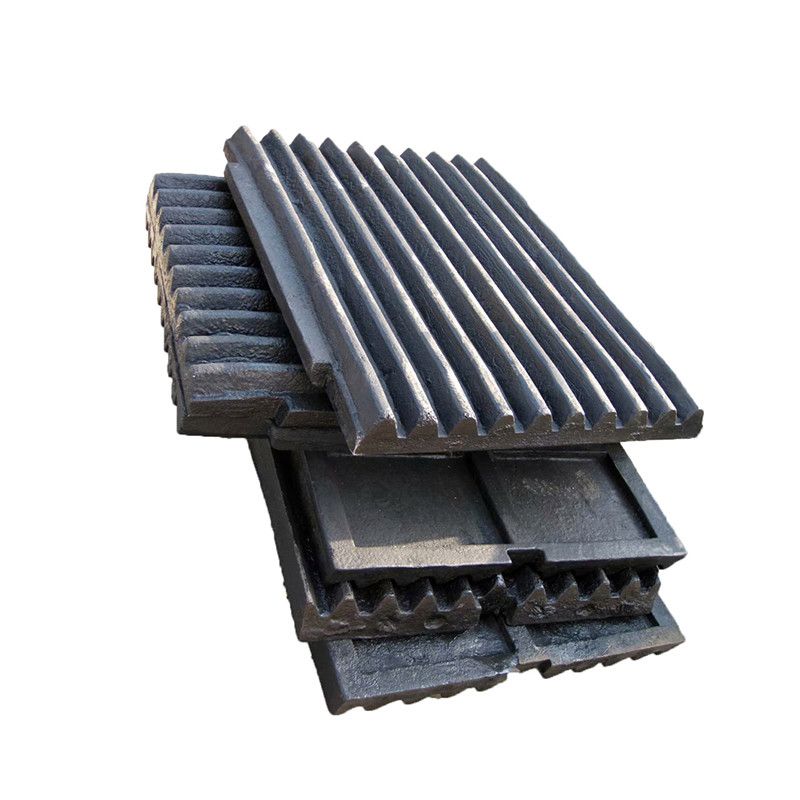

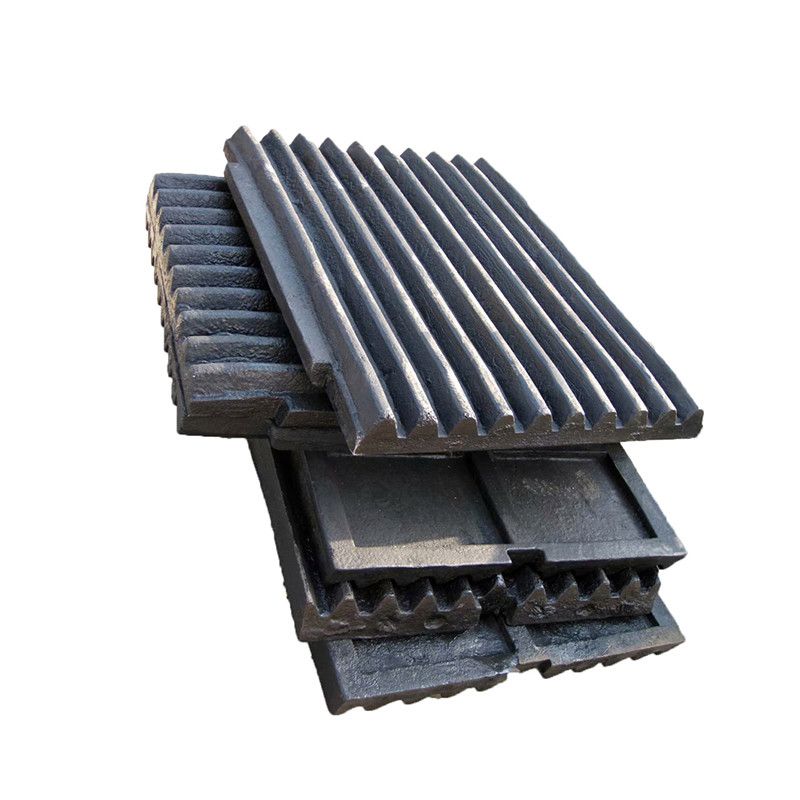

Stone Crusher Jaw Plates

Jaw plates produced by CHERRY are used to crush hard materials such as stones and ores and are a crucial component in crushing machinery. These jaw plates are threaded from high-quality material and are designed to endure pressure and wear out to give long and productive services. They are designed in such a way that they can achieve the best results in industries like mining, quarry industries, and construction industries. As sharpened and strengthened, these plates contribute to efficient crushing by preventing frequent changes while improving the crushing rates. With higher density and strength, CHERRY Stone Crusher Jaw Plates are suitable for producing construction aggregates from fresh raw supplies.

Stone Crusher Jaw Plates Manufacturer

Selecting the right manufacturer of Stone Crusher Jaw Plates has to be done carefully since such parts work at exposure and are heavily loaded with crushing operations. CHERRY is one of the most trustworthy manufacturers who use quality materials and accurate work to create robust jaw plates available in different dimensions to match the described crusher type. High-quality and reliable jaw plates take less wear and thus are less likely to give in than a less efficient operating jaw crusher. In addition, CHERRY manufactures highly durable items and upon purchase, they are willing to provide support in case of any technical issues together with spare parts for your equipment. Choosing a reliable manufacturer ensures that the jaw plates are selected to do the job, can withstand the harsh conditions, and provide the necessary durability for the job.

Stone Crusher Jaw Plates Supplier

Selecting a supplier for Stone Crusher Jaw Plates is crucial since such a part operates under critical loads and demanding applications require it to withstand crushing forces. A trustworthy supplier such as CHERRY offers jaw plates for various crushers, effective to perfectly fit into the location hence, improving performance. When you decide to order your jaw plates from a manufacturer of the respective brand, you are assured of obtaining high quality items that are made of very strong and durable materials that do not wear out very fast and require replacement. They also offer excellent customer service if you need assistance with your crushing machinery or replacement parts Choosing a reliable supplier guarantees your jaw plates to have a longer working time, high performance, and improve the efficiency of the crusher in hardworking settings.

Stone Crusher Jaw Plates Price in India

Prices of stone crusher jaw plates are determined by specific factors of Jaw plates. Generally, it costs 90 INR to 1,00,000 INR per piece based on the material and size of the pashmina. For example, the prices of manganese steel jaw plates are around 175 INR per kilogram and some of the specific costs vary from 2.4 lakh INR for larger size plates. These plates are available in various dimensions of sizes to ensure the compatibility it has with various models of crushers in use. Also, since buying in large quantities helps firms negotiate for lower prices, it is cheap for firms to carry out. Selecting genuine jaw plates from reliable manufacturers guarantees high-quality service-grade plates but also helps to improve the efficiency of the stone crushing activities hence improving the operations cost.

Why CHERRY Is the Best Brand For Your Stone Crusher Jaw Plates?

CHERRY is the best brand due to these compelling reasons:

Superior Quality

CHERRY currently employs the best quality materials and that is why the jaw plates used are of the best quality that will stand the test of time in the harsh environment of the crushing zone.

Precise Engineering

Their jaw plates are made with precision in mind so that they can custom-fit many crusher models.

Enhanced Performance

CHERRY’s jaw plates enhance efficiency in crushing, lower wear, and tear, and overall enhance the productivity of the equipment.

Wide Range of Sizes

It comes in various sizes to meet the various needs of users because CHERRY’s jaw plates are designed to be versatile.

Stone Crusher Jaw Plates Features

High Manganese Steel Construction

Jaw plates are normally constructed of high manganese steel which affords unmatched abrasion and wear protection.

Hardness Range

Jaw plates are made of high tensile strength Steels with a Brinell hardness ranging between 190 and 240 HB, therefore are very strong to withstand hardcore operations

Tensile Strength

Jaw plates have yielded tensile strength of more than 850MPa that can conveniently battle tough compressive forces during crushing operations.

Customizable Sizes

Jaw plates are standard with sizes of 30 inches up to large sizes, thus facilitating compatibility with different models of the crusher.