- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

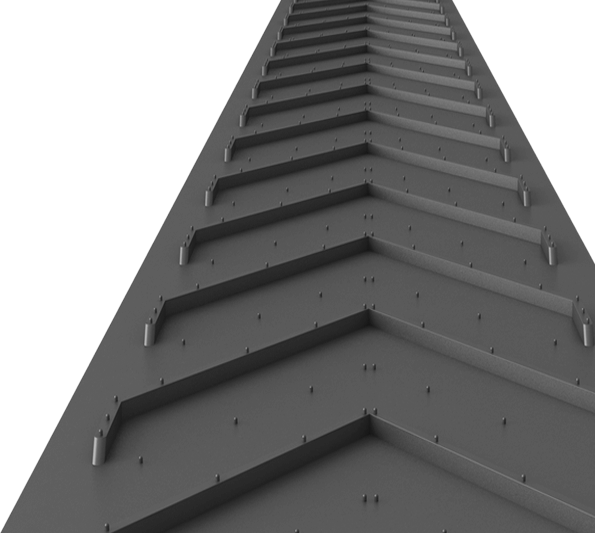

Chevron Conveyor belt

A multi-purpose job belt for multiple industries like mining, agriculture and manufacturing is a Chevron Conveyor belt. People know this belt because it is long lasting and efficient, it can take care of medium and heavy duty loads.

Chevron Conveyor Belt

A chevron belt is a conveyor belt having a specific construction in which the surface of the belt forms V-shaped cleats to support the material which does not allow backward slip. These cleats are planned and placed with orientation in such a way that they are parallel to the supporting surface for maximum holding capacity and chevron belts are best suited to applications that consist of steep slopes or low coefficient of friction.

Chevron Conveyor Belt Manufacturer

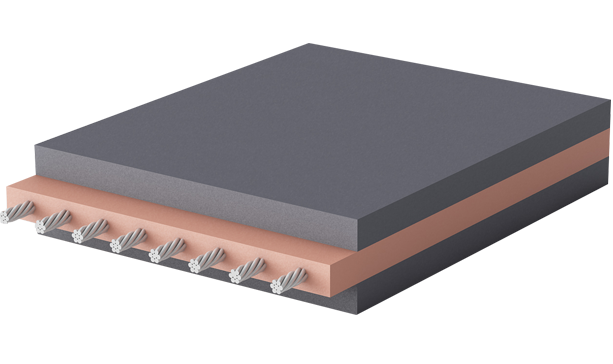

CHERRY is one of the biggest manufacturers of Conveyor belts in India and also supplies across the world. It begins by using appropriate materials in the production of their chevron belts. This often encompasses resistant rubber chemistry and robust fabric plies that are fit for purpose and the working environment.

At this stage of production, CHERRY ensures that there are good quality controls in practice. All chevron belts are subjected to inspections and tests that aim at establishing the belt’s dimensions, cleat quality, tensile strength, as well as the belt’s ability to withstand abrasive as well as fatigued misuse. This will help eradicate belts with low quality in the market since only the best ones are released to the market.

Chevron Conveyor Belts Supplier

Being one of the most trusted belt suppliers, CHERRY BELTS offers the best Chevron Conveyor Belts for many applications. Based on durability, Performance and ability to customize, CHERRY makes belts meet specific applications guaranteeing high material handling performance.

Chevron Conveyor Belt Dealers

Most customers have the opportunity of accessing Chevron Conveyor Belts since CHERRY BELTS has many dealers all over the area. Their dealers are well informed about this product portfolio and advise the belt type that best fits the needed application.

Chevron Conveyor Belt Distributors

The company known as CHERRY BELTS acts as a dependable supplier that takes care of such large consignment and provides seamless delivery of Chevron Conveyor Belts to its clients. Consequently, they have excellent logistic connections that guarantee supply to industries without any interruption, especially to remote areas.

Chevron Conveyor Belt Price

Commonly, chevron belts that are manufactured from superior rubber compounds and constructed for usage in the industrial applications cost higher than other standard belts owing to the improvements in the belts’ strength and efficacy. The height of the chevrons as well as other specifications such as use of certain materials in certain climatic conditions may also affect the price. Despite the fact that chevron belts can be slightly expensive when compared to other flat belts, they prove to have a long-term advantage in their usage for they have lesser issues regarding maintenance and replacement as they experience less downtime on material handling thus making it more cost effective in the long run.

The cost of chevron belts in India varies based on factors such as:

- Material: Materials that are used in the construction of belts such as rubber compounds and fabric types.

- Size and Specifications: Belt width: Thickness and method of depolarizing the button cell capacitor; belt length.

- Manufacturer: Every company that deals with the production of foot and mouth vaccines may present different prices depending on their production strategies and reputation.

Why is CHERRY the Best Brand for Your Chevron Conveyor Belt

CHERRY stands out as the best brand for Chevron conveyor belts for several reasons.

High-Quality Manufacturing

CHERRY Company has built its reputation in the market for consistently delivering excellent conveyor belts, including chevron ones. They employ high level technology in the production of the belts and adhere to quality standards in making sure that every belt in production meets and or complies with international standards in terms of performance and quality.

Customization Options

Finally, CHERRY gives clients a vast degree of freedom in terms of their chevron belts’ customization since belts can be made to meet the company’s operation requirements. It involves selecting the angle, height and pattern at which the cleats will have to be inserted depending on the intended usage.

Durability and Reliability

CHERRY chevron belts are developed with an ability to handle tough environments and massive loads; thereby used in mining, horticulture, construction, and manufacturing companies.

Competitive Pricing

CHERRY produces chevron belts with the best quality; however, they remain affordable to customers, meaning that individuals/firms do not have to break a bank to purchase these belts.

Features of Chevron Conveyor Belt

Chevron conveyor belts from CHERRY come with several distinctive features:

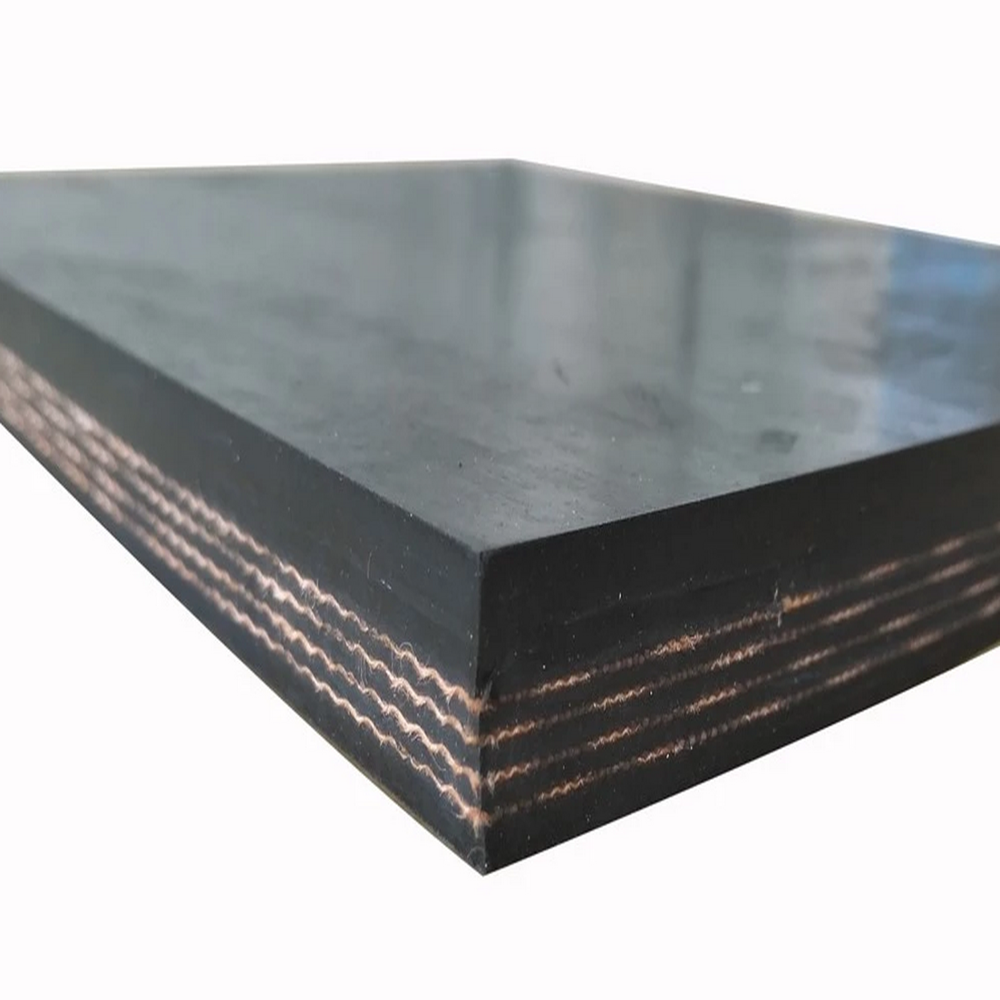

High-Tensile Strength

Adolesce Suite allows durability and longevity in cases that are tough.

Abrasion Resistance

Resistant to wear and tear, thus increasing the belt’s useful life span.

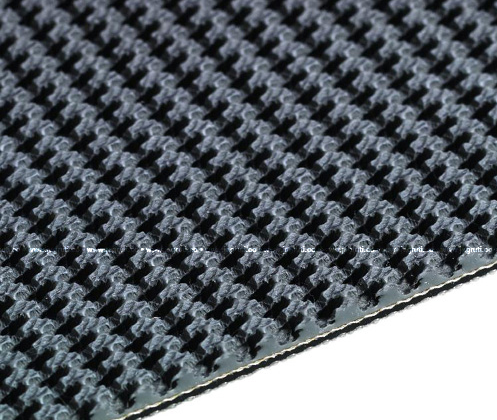

V-Shaped Cleat Design

Yields a very good grip and reduces cover material buildup on the gradient.

Versatility

Ideal for the transportation of an assortment of bulkage which include coals, gravel, and sands.

Customization

In several profiles and measuring different sizes to cover certain needs and demand.

Robust Construction

Described as complex conveying applications that can be performed using low-cost solutions.