- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

Crushing Screen Plant Conveyor Belt

CHERRY Belts being one of the leading conveyor belt manufacturers and suppliers for the crushing and screening plants industry had to face the challenge. These belts are useful in several industries including the mining operations, construction, and aggregate processing which involve conveying of materials through different stages of crushing and screening.

Crushing Screen Plant Conveyor Belt Manufacturer

CHERRY Belts specialize in manufacturing conveyor belts used in crushing screen plants; our company is focused on a long-term objective of delivering conveyor belts that are in compliance with acceptable industry quality. Advanced technological processing and high quality inputs make conveyor belts which are more efficient, longer lasting and tougher to corrosion. Quite expectedly, suppliers like CHERRY Belts have the right sort of experience and skills in their field; they know what the clients require and they supply products that can readily address the requirements of the crushing and screening plants in relation to material handling.

Crushing Screen Plant Conveyor Belt Supplier

CHERRY Belts is also another corporation dealing in the supply of conveyor belts used in crushing and screening companies, located in both the domestic and international markets. Currently the company boasts of an efficient and reliable supply chain that creates a platform of delivering their products on time. CHERRY Belts, therefore, boasts of providing customized solutions, which focus on solving clients’ specific challenges toward operational excellence.

Crushing Screen Plant Conveyor Belt price in India

The cost of the conveyor belts offered under the brand of CHERRY Belts is reasonable which makes it possible for clients to obtain them at attractive prices while at the same time receiving high-quality products.

Factors Affecting Cost

Several factors influence the cost of crushing screen plant conveyor belts:

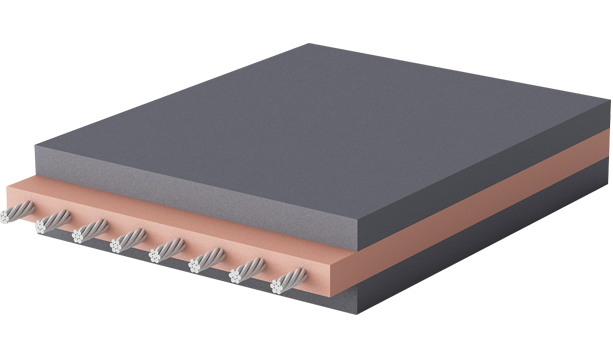

- Material Quality: The costs can be higher for better quality materials like the reinforced rubber but in exchange the end product tends to perform better and will also have a longer life span.

- Belt Specifications: They can be made in different thickness, width and length, which may also vary the prices.

- Order Volume: Purchasing large quantities for the entire company can usually be obtained at a cheaper price per unit, because of the volume buying.

- Manufacturing Technology: Technological methods of production may be costly at the beginning but would produce better quality products.

Why is CHERRY the Best Brand for your Crushing Screen Plant Conveyor Belts?

CHERRY Belts stands out as the best brand for your chevron crushing screen plant belts for several reasons:

Quality Assurance

CHERRY Belts is very particular when it comes to quality and works under the highest industry standards when it comes to manufacturing their conveyor belts.

Expertise and Experience

CHERRY Belts gives premium importance to quality control standards and hence every conveyor belt that reaches the clients has met very high quality industry standards.

Customer Satisfaction

As for the organizational culture component, the company is customer-oriented, and learners can avail optional service and assistance to guarantee the best outcome.

Innovation

They also embrace research and development to come up with better and improved products, which is evident in CHERRY Belts.

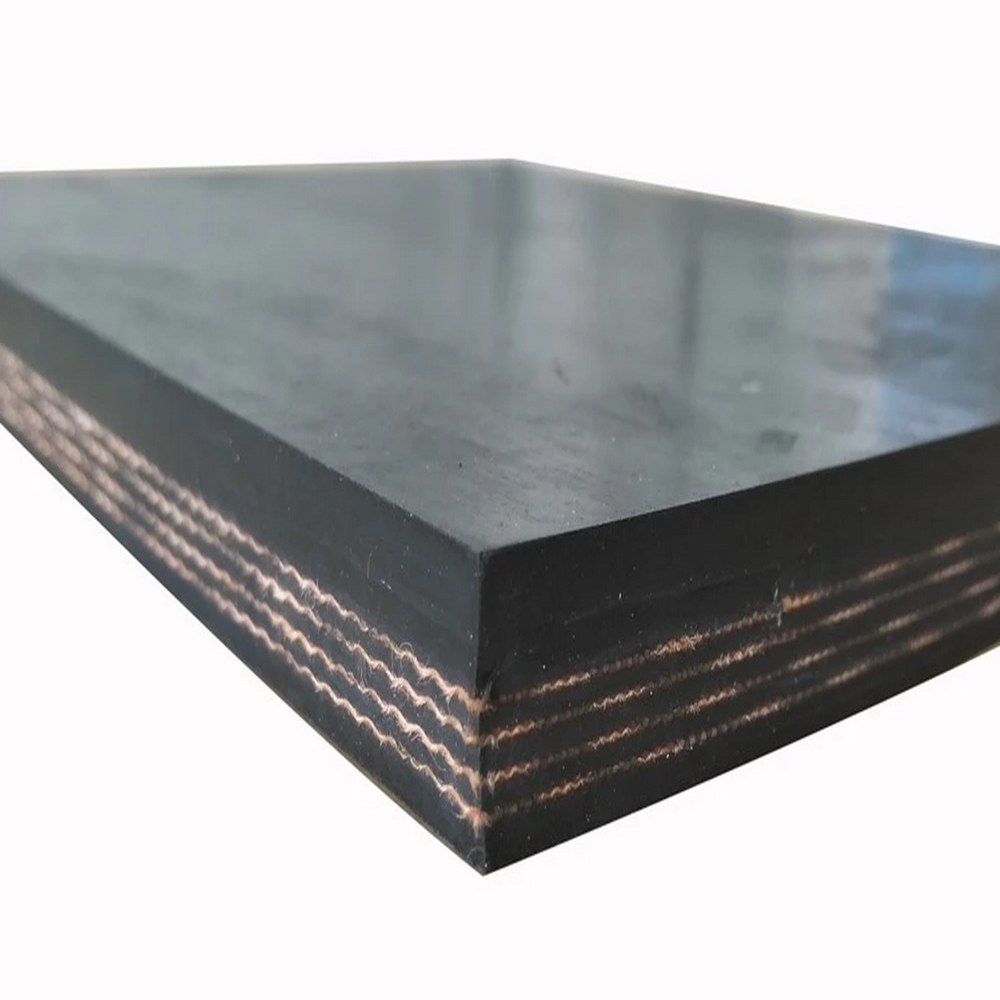

Features of Crushing Screen Plant Conveyor Belt

Crushing Screen Plant conveyor belts from CHERRY Belts are designed with several key features that set them apart:

Durability

These belts are made from high quality components since they are used in crushing and screening jobs that are rather rough.

High Performance

These conveyor belts from CHERRY Belts are designed with the best performance in mind to handle all materials uniformly and with little to no interruptions.

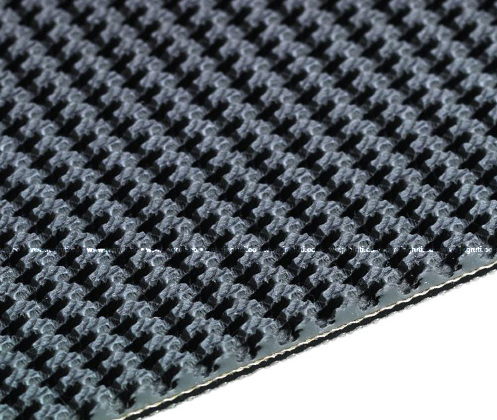

Flexibility

The belts boast great versatility – in ability to adapt to different layout plans and uses in crushing and screening stations.

Abrasion Resistance

These belts offer enhanced durability concerning wear and tear thus enhancing the use of the belts.

Low Maintenance

As CHERRY Belts’ conveyor belts are designed to need little to no maintenance, it helps Businesses save money and time frequently associated with the maintenance of conveyor belts.