- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

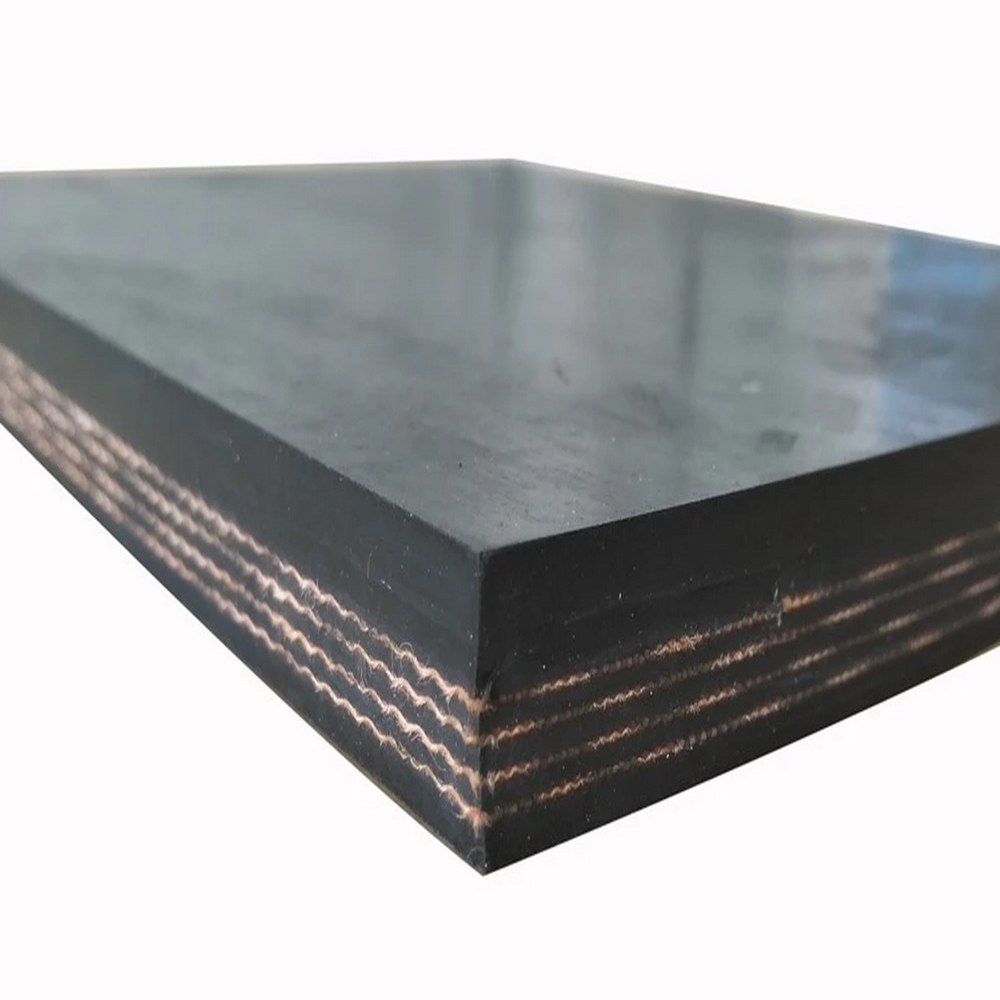

PVC Conveyor Belt

They are significant parts of many procedures and necessary in a wide range of manufacturing industries. These belts are constructed from polyvinyl chloride to ensure that these are long wearing and suitable for material handling chores. PVC Conveyor belts are very strong with high tensile strength they do not wear easily and serve their purpose effectively irrespective of the working environment. The kind are ideal for general and intensive applications in areas like: packaging, food processing industries, pharmaceutical, and many others.

PVC Conveyor Belt Manufacturer

CHERRY Belts is best recognized in PVC Conveyor Belts manufacturing. Modern production line and a group of highly-qualified specialists guarantee that every CHERRY Belts’ belt has top characteristics. Its use of technology coupled with quality check ensures that it delivers belts that meet the demand of industries which are very much demanding when it comes to their materials.

PVC Conveyor Belt Suppliers

Being among the most reliable PVC Conveyor Belts suppliers, CHERRY Belts has affirmed its capability to provide its products that would fully fit the clients’ requirements. PVC Conveyor Belts available in various sizes and thickness and manufactured according to the specification of the industries. Through on time delivery, quality products and even superb customer relations, CHERRY Belts has become the go to supplier for many businesses across the country of India.

PVC Conveyor Belt Price in India

Specifically, the organization offers affordable PVC Conveyor Belts for its clients while observing the quality of the product. The PVC Conveyor Belt comes in different sizes, thicknesses and due to the specific need of the application, the price will vary. Most of the belts in CHERRY Belts are reasonably priced and with that, customers are provided with high quality belts for their money hence the case of value for money.

Features of PVC Conveyor Belt

- High Tensile Strength: Promotes the product’s steadiness and the durability of the product to the consumer.

- Abrasion Resistance: Lasts long due to wear and tear hence good for demand industries that need strenuous activities.

- Versatility: Can be recommended for many industries and tasks that require precise positioning.

- Chemical Resistance: They are resistant to water, weak acid, alkali solutions, most of the chemicals, oils, and greases.

- Easy Maintenance: Easy to clean and maintain, ultimately lowering operation expenses and seizing operation time.

Why CHERRY is the Best Brand for your PVC Conveyor Belt

Quality Assurance

The quality assurance policy of CHERRY Belts is put to practice to make certain that each belt offered to consumers conforms to the company’s benchmarks.

Customization

Comes in various sizes and precisely that is suitable for certain industrial use.

Advanced Manufacturing

Is vital in the development of new technology in the production of this product; uses proper techniques in belt making.

Customer Service

Pre and post-sale technical support team that ensures clients are well guided in their usage of the software.

Benefits of using High Quality Conveyor Belts

Conveyor belt prices depend in aspects such as the type, material, width, length and added features on the belt. Besides, costs may vary depending on the country and special reference to the environment of Delhi could be taken.

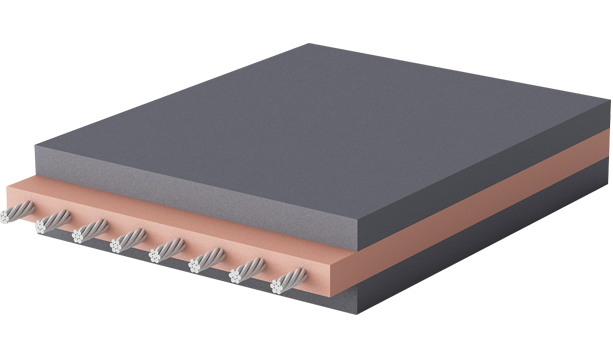

Type of Conveyor Belt

Depending on the need of the application Conveyor belts can be of rubber, PVC, PU, or modular type belts can be used. For example, belts such as heat or oil resistant belts are normally more expensive than ordinary belts.

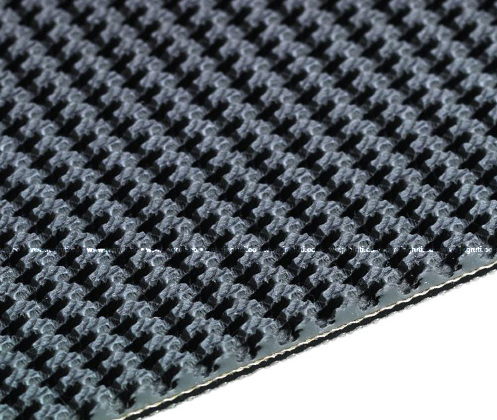

Material and Construction

Some factors that could cause belt price variation could include the strength of material used, the tensile strength or other physical characteristics that affect the durability of belts. There are those that are of high quality that give them longevity and higher performance as compared to the others and they are expensive.

Customization and Accessories

The extra provisions such as cleats, sidewalls, and V-guiding are other contributing factors to the final price. Small Conveyor Systems will have a lower cost because they have general application in industries; whereas, conveyors that would have been designed to suit a particular need will cost higher since they will have to undergo engineering and fabrication.

Dimensions

The length and width of the conveyor belt are also held in consideration when coming up with the cost of the equipment. Although the length of the belt can be changed easily, the width of the belt makes a significant difference with the longer and wider belts needing more material and thus are more costly.