- Bangalore, Delhi, Ahmedabad, Mumbai, Dubai

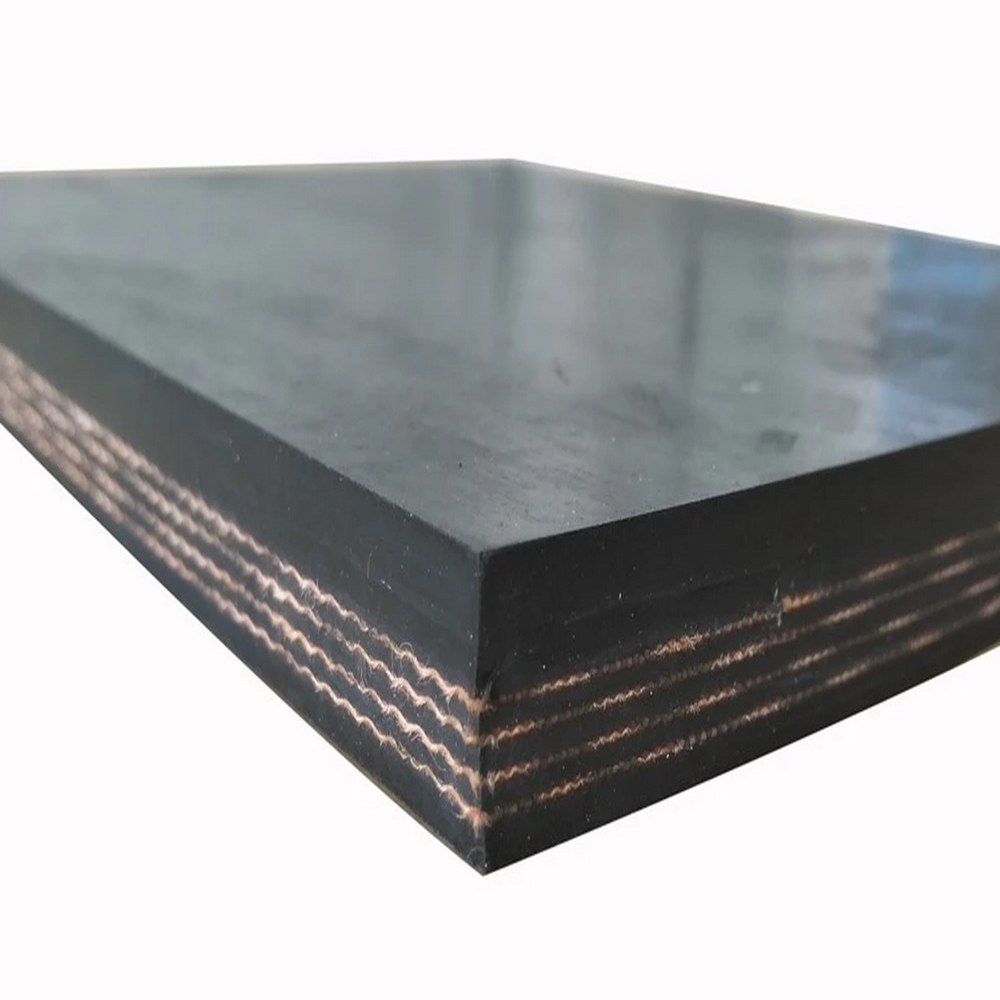

Rubber Conveyor Belt Manufacturers in Delhi

Delhi’s industrial sector has critical requirements for dependable high performing equipment to support its production needs. Out of all the requirements in the industrial field, the most important function is in the handling and movement of materials using a conveyor belt. CHERRY Belts is one of the leading manufacturers of rubber conveyor belts in Delhi that has a huge stock of belt ranges for the various industrial applications including mining, constructions and logistics industries. On our rubber conveyor belts, we employ a great advance technologically to the extent of strength & durability as well as the long lasting even under high demanding applications. Thus, manufacturers in Delhi can be assured of getting a brand in CHERRY Belts that offers quality and high performance to its products.

Get the Best Rubber Conveyor Belt in Delhi from CHERRY Belts

If you are in need of the best rubber conveyor belt in Delhi then your best bet will be on CHERRY Belts. It is informed that our products are made to its high quality and accuracy to fit a variety of industries. We have years of experience, and that is why Industries understand the requirements in Delhi because we offer belts that meet requirements of high standards. Our conveyor belts undergo durability tests, carrying capacity tests, and thermal tests implying that the conveyors tested are fit for demanding conditions and consistent use. Selecting CHERRY Belts is the assurance of working with a quality product with an assurance of superb performance and durability.

Rubber Conveyor Belt Supplier in Delhi

We are not only a manufacturer; we are a leading supplier of Cherry Belts- the best rubber conveyor belts in Delhi. You can always rely on us for delivering safe and on-time services and products and a range of belts for industry. We also have a large stock of products and well coordinate our supply chain in order to be ready for urgent orders or orders with specifications. At CHERRY Belts we pride ourselves on being able to supply high quality products to meet your demand and our team is dedicated to making the process as simple as possible. These characteristics of quality and service make us a pointed out supplier of conveyor belts in Delhi.

Price Range for Rubber Conveyor Belts in Delhi

The cost of rubber conveyor belts in Delhi depends on the model, where the basic types of belts may cost about Rs. 500 per metre, and high end, high powered belts, may cost up to Rs. 3000 per metre. As one of the privileges that come with going to CHERRY Belts, customers get the best belts at reasonable prices. Our endeavour is to deliver maximum utility to your used money through offering high quality products at very reasonable prices and thereby making ourselves the justifiable choice for Delhi’s industrial requisites.

Additional Services

Apart from manufacturing and supplying rubber conveyor belts, you will find that CHERRY Belts provides further services to complement your belt set. We offer basic installation services on our conveyors and guarantee that all these conveyors are efficiently arranged. In addition, we also undertake after-purchase services such as maintenance and belt repair to ensure that the belts are in their best shape. Our team also provides consulting services to guide you in choosing the most suitable conveyor belt for applications that are relevant to you and therefore making CHERRY Belts your one-stop conveyor belt solutions company.

Why CHERRY Belts the Best Brand For Your Rubber Conveyor Belt in Nagpur?

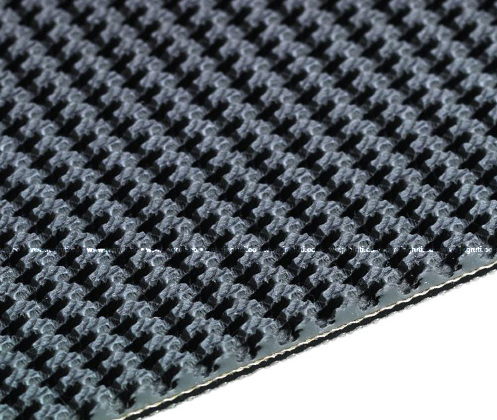

Top-Quality Materials

At CHERRY Belts, only superior quality of materials are utilised with regard to the intended durability and performance of all products.

Wide Range of Options

We have a wide range of rubber conveyor belt for different industrial uses.

Affordable Pricing

Our products were carefully priced to exploit industry opportunities yet ensure affordability and quality standards were achieved.

Exceptional Customer Support

With our proficient team, customers are assured of consultation, sale, installation, and any after-service need.

Cost of Rubber Conveyor Belts in Delhi

Material Quality

Rubber of higher quality or special material that are heat or abrasion resistant will be costly.

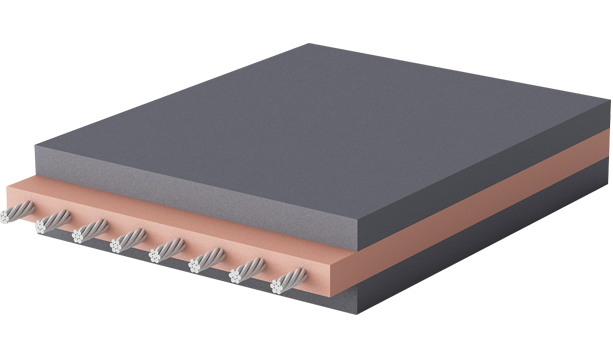

Load-Bearing Capacity

For the conveyors with higher carrying capacity the cost of the conveyor belt will be high due to the reinforced structure.

Dimensions

The nature of the belt in terms of the length, width and even thickness affects the pricing of the belt.

Temperature Resistance

It is therefore expected that belts manufactured to operate in extreme conditions will be expensive.