- Mumbai, Bangalore, Delhi, Ahmedabad, Dubai

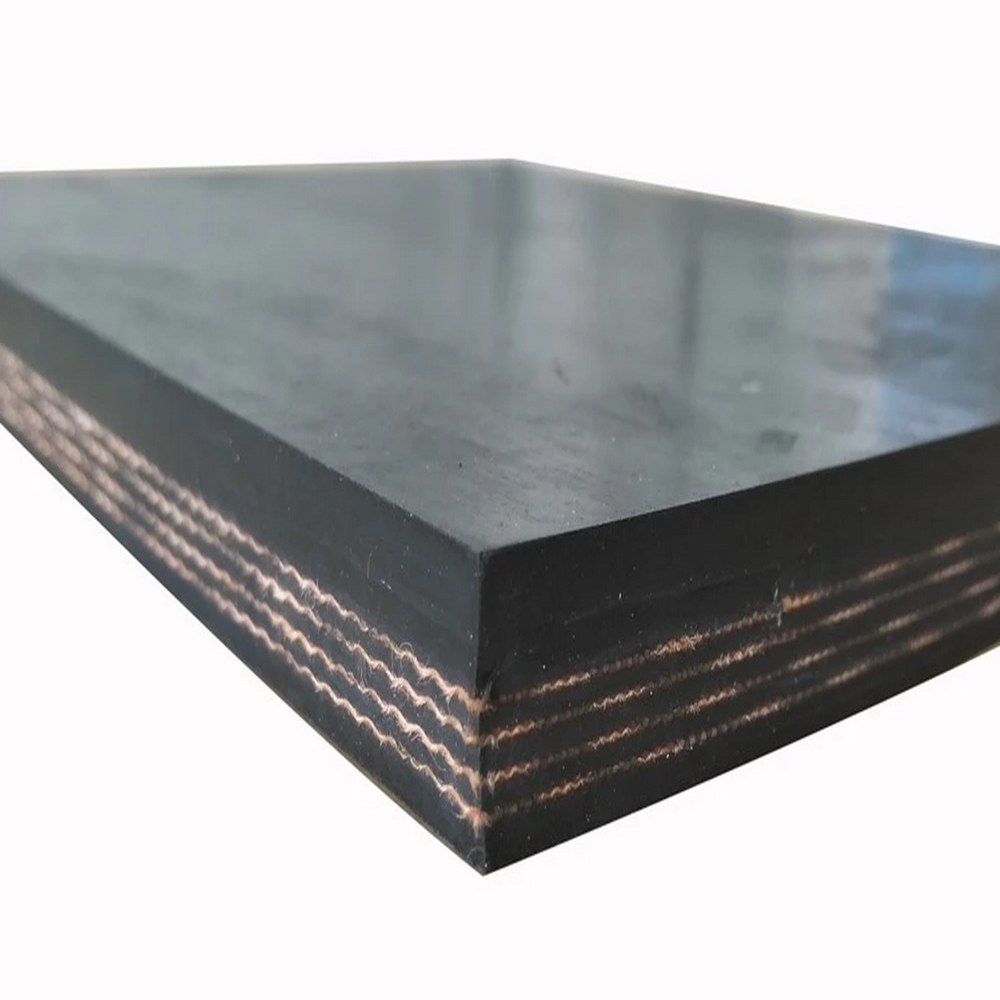

Stone Crusher Conveyor Belt

At Cherry-The Super Engineer, we pride ourselves on being a manufacturer and supplier of superior quality conveyor belts especially for the stone crushing industry. These conveyor belts are used in the material handling in stone crusher plants as the best solution for transporting materials.

Stone Crusher Conveyor Belts Manufacturer

At Cherry we produce all types of conveyor belts suitable for the stone crusher industries to meet their needs. The conveyor systems used by stone crushing plants cannot overemphasize its role bearing the sheer weight of the material it is to transport such as stone, gravel, sand and minerals. These belts must be strong, effective, and designed to endure the demand of operation as is continuously run.

Stone Crusher Conveyor Belt Dealers

The company is tied with many dealers and distributors so as to supply Stone Crusher Conveyor Belts of good quality in a region. These dealers are well experienced and provide the clients with the necessary information concerning the conveyor belts and manufacturer specifications in relation to uses, assembling, and conductivity. For this reason, they give individual approaches to guarantee that the belts will meet specific needs in terms of width, length, or load-carrying capabilities.

Stone Crusher Conveyor Belt Distributors

The distributor of CHERRY BELTS always monitors the availability of Stone Crusher Conveyor Belts to ensure the necessities for urgent orders and for large projects. They focus on sourcing products that will be delivered fast in order to reduce interruptions in operations. Distributors also insist on quality of products so that their products meet customers’ required standard of quality, durability and performance. Collectively, CHERRY BELTS dealers and distributors create a strong supply chain network that provides unmatched customer support and application engineering to segments that use stone crusher conveyor belts.

Cost of Stone Crusher Conveyor Belts

The specific cost of stone crusher conveyor belts may differ according to the type of belt whether rubber or PVC, the type of material used, belt length and width and any specific customization that the client may desire. Pricing policy at Cherry: We provide reasonably low prices in comparison with companies’ average, and at the same time, we work to guarantee high quality and durability of products.

Factors Affecting the Price:

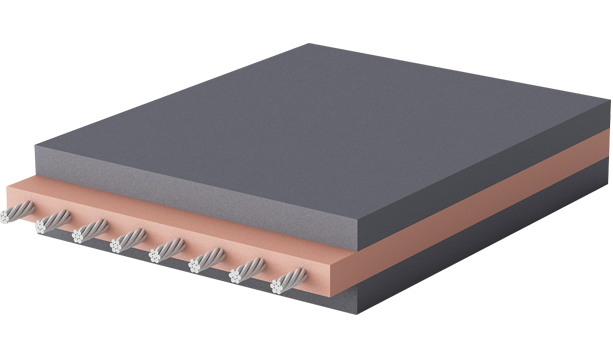

- Material Quality: Some types of rubber are reinforced and some other polymer compounds are more expensive by their nature since they provide increased durability and other properties are fundamentally better.

- Belt Length and Width: As the size of the belt increases, the amount of material to be used and the manufacturing time also increase resulting in increased costs.

- Load Capacity: There is the need to add extra slides and ensure that the belts used have better quality, thus the price is likely to be high for belts that should handle more capacity.

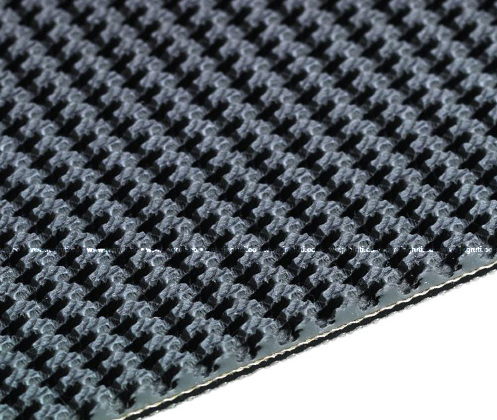

- Temperature and Abrasion Resistance: Belts that have heat resistance or better abrasion of material are typically costly because they’re made using better material and/or technology.

- Customization: The costs can also be affected by the specifics of the operations in which the pipes will be used and the need to incorporate some features in the design of pipes; for instance, chevron patterns will cost differently than normally designed pipes which will also be different for inclined transport or pipes of some particular dimension for a certain setup.

- Market Demand and Supply: There are times when market demand may change or the availability of some of the raw materials to make a specific product may be affected relative to earlier periods affecting its price.

Why is Cherry the best brand for your Stone Crusher Conveyor Belts?

At Cherry, The Super Engineer we endeavor to deliver a better conveyor belt that creates efficiency and productivity of Stone Crusher Plants. Theatrals’ product range, quality, and client-centered business practices explain why it has become a popular choice among its clients.

Proven Track Record

Cherry conveyor belt has been in the market for more than 50 years making it one of the most popular conveyor belts manufacturers.

Quality Assurance

All the products are ISO 9001:2008 certified to depict the company’s adherence to quality and performance.

Global Reach

Our company has a wide range of connections all over the world and has supplied our conveyor belts to more than 100 different countries depending on the industrial requirements.

Customer-Centric Approach

In order to address each client’s needs differently, we ensure that we speak to our clients and understand them fully.

Use of Conveyor Belts in Stone Crushing

Conveyor belts are used in various stages of stone crushing operations, including:

Feeding the Crusher

Conveyors transfer feed from the belt feeder hopper through the primary crushers.

Transferring Between Crushers

From the primary crushers the material is transported to secondary crushers by conveyor belts or screens.

Stockpiling

After the material has been broken into the correct size, by conveyor belts the end product is placed in a stockpile.