- Bangalore, Delhi, Ahmedabad, Mumbai, Dubai

Stone Crusher Gearbox Manufacturer In Chennai

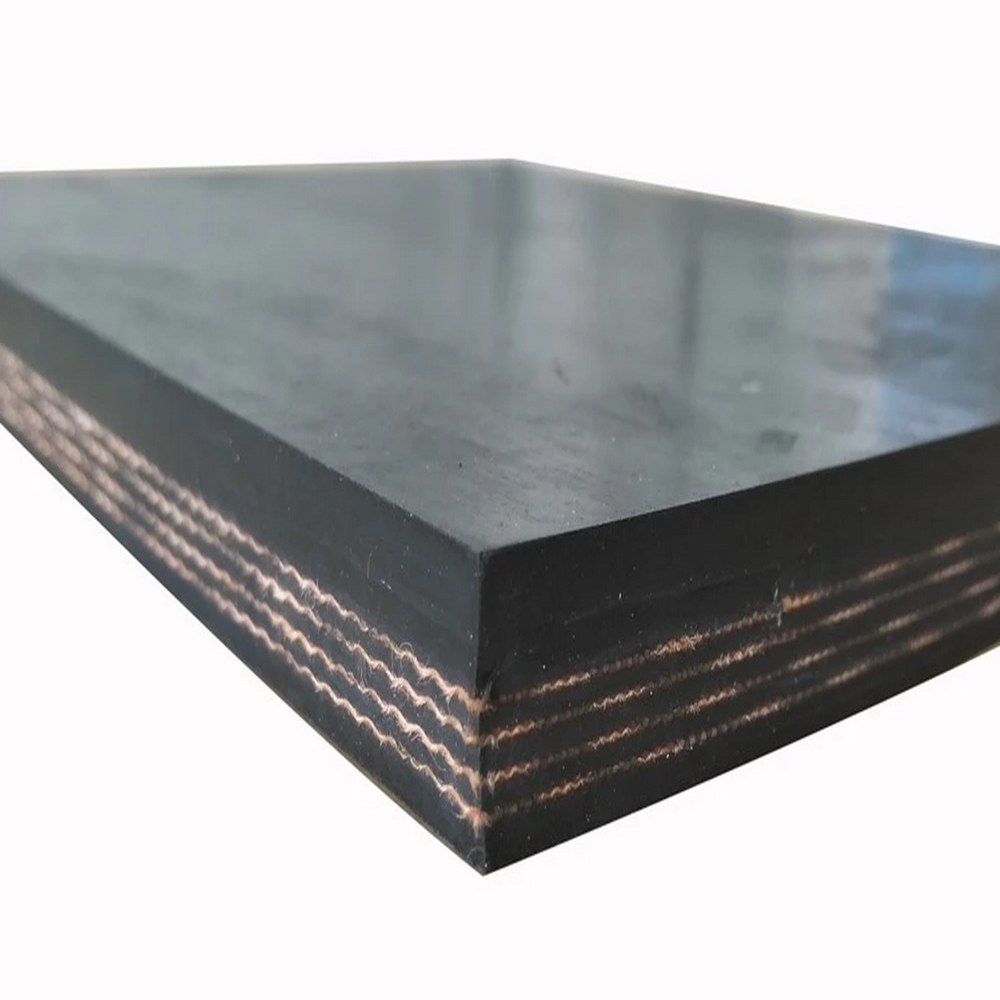

Stone crusher gearboxes produced by SPECIALER play an important role in crushing equipment and the efficiency of its working by transmitting power to equipment. As these gearboxes are intended for mining, quarrying, and construction undertakings, the contaminants are engineered to withstand the prevailing environment. SPECIALER gearboxes are well-engineered to provide the right level of crushing raw materials from big stones to small aggregates.

They are robust in construction, thereby providing low maintenance and less time is spent on repair hence long service. These gearboxes play the role of improving efficiency and productivity crushing stone equipment thus making it compulsory to avail them. This makes Chennai’s stone crusher gearboxes of high quality and Hence makes the gear’s reliability a very important component of any industry’s smooth operation.

Stone Crusher Gearbox Manufacturer

Choosing the correct supplier for stone crusher gearboxes was necessary given that the equipment is subjected to high stress and is expected to manage heavy loads. SPECIALER guarantees that all their gearboxes are manufactured from quality material and are also designed to handle the conditions in mining and construction facilities.

Some of the latest models of gearboxes used in stone crushers are very durable and to ensure they maintain that durability, they do not require a lot of maintenance. They also offer the best services and they have the fastest access to spare parts to fix the machinery. Selecting the correct manufacturer allows the Stone Crusher gearbox to be very efficient and has a very long lifespan.

Stone Crusher Gearbox Supplier

SPECIALER is particularly preferred for the provision of stone crusher premium gears. SPECIALER, as a leading provider, is committed to providing consumers with only the highest quality, most lasting gearboxes. These providers use advanced technology, highly qualified workers, and quality assurance standards to produce long-lasting and dependable gears and gearboxes.

This dedication has resulted in them becoming one of the leading stone crusher gearbox sellers nowadays. As a result, they have established themselves as affordable partners for long-term reliable gearboxes, particularly for stone-crushing sectors that require consistent stone crushing with their efficient and dependable machinery.

Stone Crusher Gearbox Price in India

When comparing the cost of stone crusher gearboxes in India, keep in mind that the cost will increase based on the gearbox’s size, appearance, and unique characteristics. As observed in the structure of Indian markets, product costs are very affordable, and SPECIALER provides clear rates with no extra costs.

These providers provide value for money by ensuring that the gearboxes they manufacture are both inexpensive and of excellent quality, saving the user a significant amount of money in terms of recurring maintenance costs and replacement of worn-out components. Fair pricing practices, combined with high-quality production, make these gearboxes a very cost-effective investment for any firm. In this manner, by choosing the most cost-effective, high-quality stone crusher gearbox, the company may improve its operations without incurring additional costs.

Why SPECIALER Is the Best Brand For Your Stone Crusher Gearbox?

When selecting the best manufacturer for the stone crusher gearbox, SPECIALER stands out for various reasons:

Outstanding quality

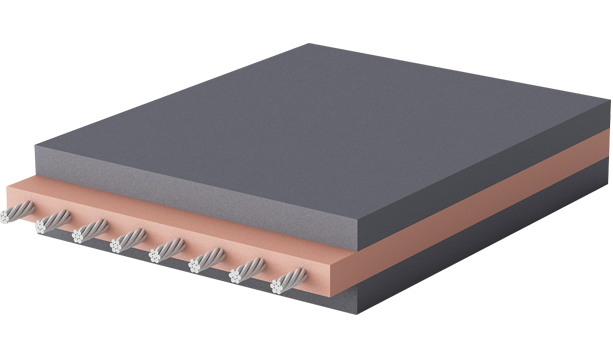

All SPECIALER gearboxes are constructed using high-quality materials to provide effective and long-lasting operation irrespective of the surroundings.

Cost Effective

It has an experience of more than 50 years starting from 1961, which is why they provide expert care and top notch workers and team.

Strong Image

SPECIALER has established itself as one of the most dependable and professional organizations in the market due to its extensive experience.

Customer Support

SPECIALER also provides great after-sales service, assisting customers in effectively getting their gearboxes to run.

Features of Stone Crusher Gearbox

Robustness

Stone crusher gearboxes have the capacity and are strong enough to withstand some of the worst environments and huge loads over time.

High Capacity

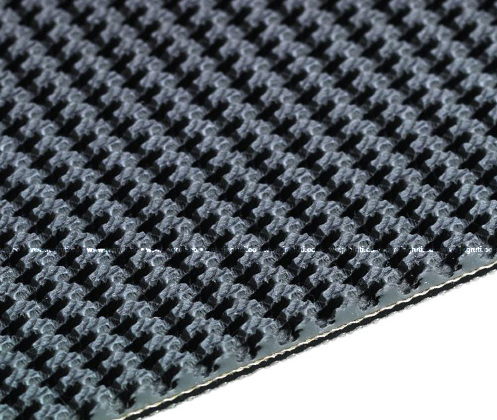

These gearboxes deliver quick and trustworthy performance in the most demanding environments, making sure crushing processes work smoothly and efficiently.

Low expense

Stone crusher gears are built for maximum durability and have lengthy intervals between maintenance checkpoints, resulting in minimal operating costs.

Versatility

Stone crusher gearboxes are global and must be adaptable to a variety of applications in mines, quarries, and other facilities.